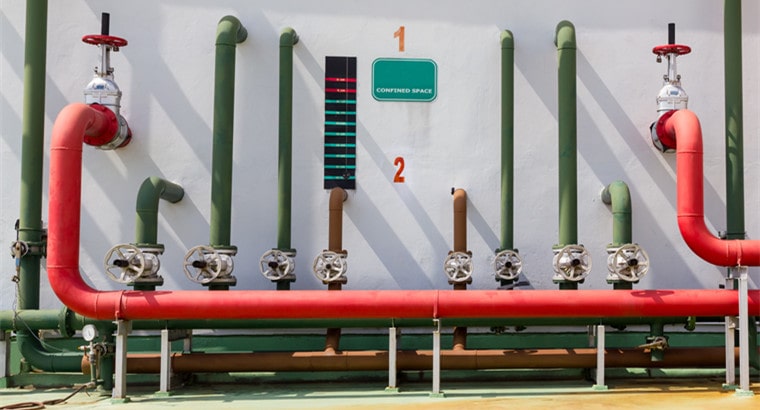

If you’ve ever had to align two pieces of equipment in your industrial facility, you will likely have needed to address flange alignment. Understanding exactly what this is and the best ways to perform flange alignment can make a noticeable difference in both time spent on completing projects and the accuracy of said completed projects.

In this article, we will be delving into flange alignment methods, so you know how to carry out such tasks easily in any industrial environment properly!

What is flange alignment?

Flange alignment is an essential process used to connect two pipeline components. It is a precision procedure that includes properly aligning two mating flanges and bolting them together with a gasket, ensuring they are connected correctly and securely. It can cause unacceptable stress on the bolted joint without proper flange alignment and, in some cases, even result in flange or gasket failure.

The use of equipment such as visual inspection tools, dial indicators, inside calipers, bubble levels, and optical levelers can be useful to ensure quality alignment. This offers greater accuracy than using observational methods alone. Flange alignment is conducted before installing any pipes or components to reduce potential problems that could occur down the line, such as leaks and corrosion.

General Procedure

Choose the gasket to be used with the flanges if it was previously specified or known by the pipe vendor. The flanges should be aligned. Place the gaskets in the center if they will be utilized. Connect the gaskets and flanges. Verify the alignment of the flanges.

Install the bolts. Attach the bolts to the flanges using enough force. Check that the flanges are aligned and that the flange and mating surface is properly aligned. Make sure that the bolts on the flanges aren’t over-torqued.

Optional Procedural Steps

Flange alignment tools might or might not require welding after bolting them together. Tests can be performed when the flanges are welded and tested for leaks. Flanges could be stressed to verify that bolts and flanges are not stressed too much. A third-party inspection might be necessary.

Flange Alignment Tools

Riverlake provides the most comprehensive range of flange alignment tools available. If you require just one tool or a mix of tools, we can help you get back on track quickly and safely. Flange alignment tools made by Riverlake are safer and more effective than hammers that swing at drift pins or use spud wrenches.

If you require Flange alignment pins and flange alignment equipment, Riverlake is the right place to shop for all your flange alignment tools requirements.

It’s not necessary to hammer or fight with spud wrenches, thanks to SMP’s Flange alignment pins. Put in these Cadmium (CAD) coated flange alignment pins and then turn to rectify both upwards and downwards and the rotational inconsistencies.

Titan Flange Alignment Pins offer the safest, most simple, and most economical method to align bolt holes in flanges. Pin sizes vary from 3/8” to 3/8” to 3-5/8″. The best option for flange alignment with isolation kits for bolt holes for flanges.

This FlangeBoss Mechanical flange alignment tool is specifically designed to handle situations when your flanges have been misaligned through more than one bolt hole. This tool is powered by mechanical forces and can produce as much as 10,000 lbs of force. There are two versions of the FlangeBoss Flange Alignment Tool The FAT8KM (8,000 pounds) and FAT10KM. FAT10KM (10,000 tons in force.) FlangeBoss is made in the USA.

With incredible security features and nine tonnes of force, The Equalizer brand of flange alignment tools provides an alternative solution to the same issue. Equalizer tools for flange alignment are designed to be suitable for flanges of heavy duty that are not aligned.

Hydraulic flange alignment tools have been specifically designed to align massive flanges or flanges with heavy diameters that are out of alignment. To know more about maximizing efficiency while minimizing the risk of injury for your torquing and bolting crew, contact us or make your appointment with our sales representatives today.